Production Unit and DC Location in Brazil for a Major Cosmetics Maker, and Inbound and Outbound Logistics Optimization

Determination of the optimal number of production units, their location, and industrialization profile Determination of the optimal number of DCs and their location Guidelines for logistics operations, showing major logistic flows and impact of their change Implementation plan

ACTIVITIES DEVELOPED

- Analysis of the logistics database and location on a geo-referenced basis

- Determination of the current SKU status

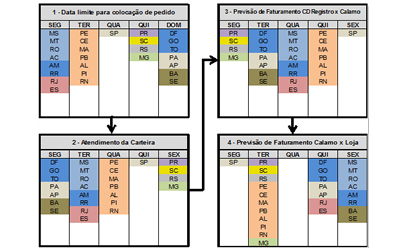

- Analysis of price structure, provisioning schedule, transfer freight profile, and distribution

- Calibration of the freight curve for modeling purposes

- Analysis of the situation and definition of scenarios to simulate

- Simulation of scenarios for the projects’ time horizon

- Analysis of each scenario, considering costs and levels of service

- Fine-tuning the solution, with analyses for micro locating new units

- Project’s business plan, with implementation schedule and costs involved

CASE STUDIES

- Study of a Distribution and Storage Network for a Food Conglomerate

- Studies to Restructure the Logistics Network of Large Companies

- Location of DCs and Improving the Logistics Structure in Brazil for a Major International Player in Consumer Goods

- Production Unit and DC Location in Brazil for a Major Cosmetics Maker, and Inbound and Outbound Logistics Optimization